Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

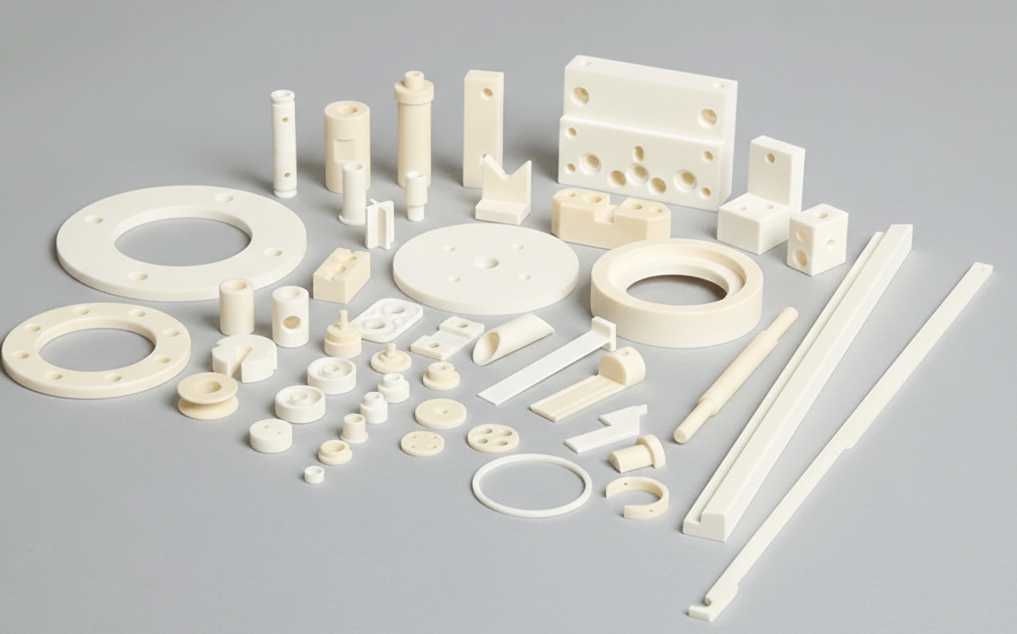

Overview

Beryllium oxide (BeO) ceramics are advanced technical ceramics known for their exceptionally high thermal conductivity, high melting point, excellent electrical insulation, and outstanding chemical and thermal stability. Combined with a low dielectric constant, low dielectric loss, and good process adaptability, BeO ceramics are widely used in special metallurgy, vacuum electronics, nuclear technology, microelectronics, and optoelectronic applications where both thermal management and electrical insulation are critical.

BeO ceramics possess a wurtzite crystal structure with strong covalent bonding and a very low average atomic weight of approximately 12.5. This unique structure results in extremely high thermal conductivity, which is typically 6–7 times higher than dense alumina (Al₂O₃) and about three times higher than MgO.

For BeO ceramics with a purity above 99%, the thermal conductivity can reach up to 310 W/(m·K) at room temperature. In practice, the thermal conductivity of BeO ceramics is strongly influenced by material purity and density—higher purity and greater densification directly lead to improved heat dissipation performance.

BeO ceramics exhibit excellent electrical insulation properties, even at elevated temperatures. The volume resistivity remains as high as 4 × 10¹⁰ Ω·m at 600 °C and 5 × 10⁹ Ω·m at 800 °C. The dielectric constant increases only slightly with temperature, while the dielectric loss remains very low, although it gradually increases at higher temperatures.

These characteristics make BeO ceramics particularly suitable for high-power and high-frequency electronic applications operating under thermal stress.

BeO ceramics demonstrate outstanding resistance to wetting and corrosion. They exhibit low vapor pressure and low evaporation rates at high temperatures. Under vacuum conditions, BeO ceramics can be used continuously at temperatures up to 1800 °C, and up to 2000 °C in inert atmospheres. However, noticeable volatilization occurs at around 1800 °C in oxidizing environments, and significant evaporation can occur at 1500 °C in the presence of water vapor.

BeO ceramics are resistant to attack by many molten metals and basic slags. However, they can be corroded by glasses containing acidic oxides, potassium hydroxide, caustic soda, and alkali metal carbonate solutions.

BeO ceramics exhibit moderate mechanical strength, with high-temperature compressive strength exceeding that of many other oxide ceramics. However, they show relatively higher creep at elevated temperatures. Under a load of 0.66 MPa, creep begins at approximately 1000–1050 °C, and deformation can reach 2 mm/m after 10 hours at 1260 °C.

BeO ceramics are classified as refractory materials and are widely used in high-temperature metallurgical applications. BeO ceramic crucibles are suitable for melting rare metals and precious metals, particularly in processes requiring extremely high material purity. These crucibles can operate at temperatures up to 2000 °C.

Due to their high melting point (approximately 2550 °C), excellent chemical stability (especially resistance to alkaline environments), thermal stability, and high purity, BeO ceramics are also used for melting uranium and plutonium. In addition, BeO crucibles have been successfully applied in the preparation of standard samples of silver, gold, and platinum.

The high transparency of BeO ceramics to electromagnetic radiation enables the use of induction heating, allowing efficient melting of metallic samples within BeO crucibles.

The combination of high thermal conductivity and low dielectric constant makes BeO ceramics highly attractive for vacuum electronics and electronic packaging. BeO ceramics are widely used in high-performance, high-power microwave packages, and BeO substrates are employed in high-density multi-chip modules.

By rapidly dissipating heat generated during operation, BeO components significantly enhance system stability, reliability, and service life.

BeO exhibits a high neutron scattering cross-section, enabling it to reflect escaping neutrons back into the reactor core. As a result, BeO ceramics are widely used as neutron moderators and radiation shielding materials in nuclear reactors.

Compared with metallic beryllium, BeO ceramics offer superior high-temperature irradiation stability, higher density, and better strength and thermal conductivity at elevated temperatures, while also being more cost-effective. These advantages make BeO ceramics well suited for use as reflectors, moderators, and dispersion fuel matrix materials in nuclear reactors.

BeO ceramics can also be used in control rods and may be combined with UO₂ ceramics to form nuclear fuel systems.

BeO ceramics exhibit both thermoluminescence (TL) and optically stimulated luminescence (OSL) properties, making them highly attractive for radiation dosimetry. BeO is particularly suitable for certain high-dose measurements, as its response is largely energy independent.

The dosimetric performance of BeO ceramics is comparable to that of LiF:Mg,Ti and Li₂B₄O₇:Mn, while offering excellent chemical, mechanical, and thermal stability—especially when used in non-toxic ceramic forms.

With their unique combination of ultra-high thermal conductivity, excellent electrical insulation, and robust high-temperature stability, beryllium oxide ceramics play a critical role in demanding industrial and scientific applications. From special metallurgy and vacuum electronics to nuclear technology and radiation dosimetry, BeO ceramics remain an essential material for advanced systems operating under extreme conditions.